In Welding Fillet The Normal Arc Length Is. To do this we employ basic algebra. Imagine if three of those fall within 12 in.

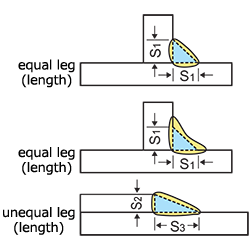

This shows a 6 fillet weld to be applied to the arrow side. This is why leg sizes are called out for fillet welds. Diameter of the core wire in the electrode What arc length gives the best blend into the edges of a weld bead.

A fillet weld with an efficient size much less than 4s or much less than 40 mm must not be utilized to carry load.

A cnom t anom2 anom1 a a nom nom nom a partially penetrated butt weld b T joint Figure 38 Effective width For T joints full penetration is assumed in the case of anom1 anom2 t 5 t cnom 319 cnom 3 mm. The effective length of a fillet weld might be taken as the total size of the full-size fillet much less one leg length s for every end which does not continue around an edge. Partially penetrated butt welds may be designed as fillet weld with an effective width of a anom 2 mm see Figure 38a. One half of the weld penetration is combined with the base measurement and this results in the arc length for a certain amperage.