Projection Welding Defects. When the projections make contact at the same time but they are different sizes they can heat at different rates. Metal thickness and composition is a significant matter here.

Welding defects may occur either outside or inside the weld metal. However one potential difficulty for the success of projection welding is the cleanliness of the parts or presence of surface films that can inhibit bonding. When the projections make contact at the same time but they are different sizes they can heat at different rates.

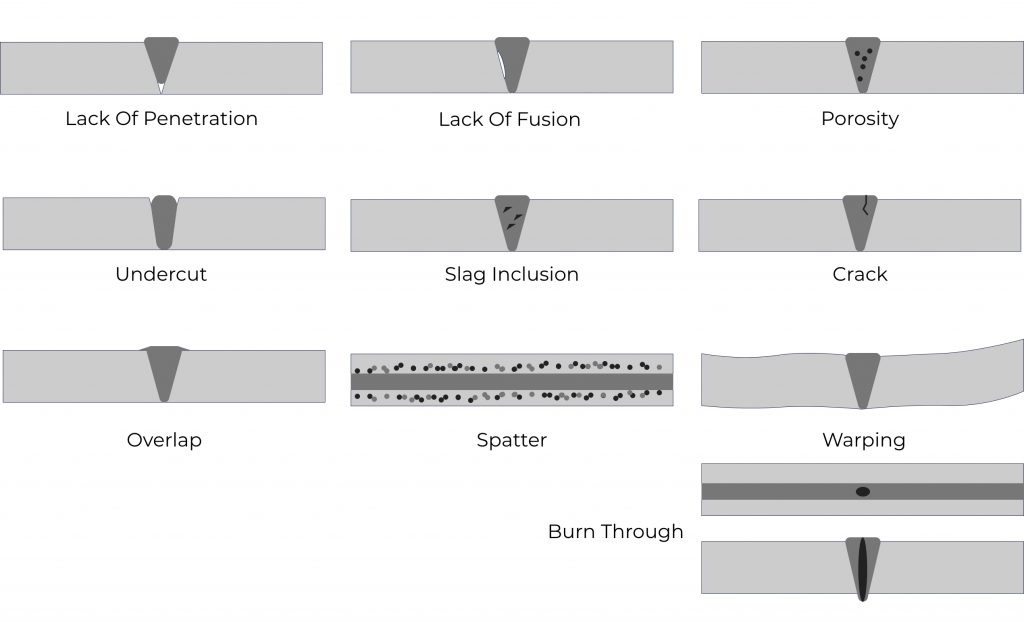

Welding defects are generated in a welding job due to the faulty or poor technique used by the inexperienced or unskilled welder or due to fundamental difficulties in the welding operation.

Some of the defects may be allowed if the defects are under permissible limits but other defects. Resistance Projection Welding A resistance welding process in which coalescence occurs at one or more small contact points on parts Contact points determined by design of parts to be joined May consist of projections. 2 when current is applied weld nuggets similar to spot welding are formed at the projections. ExpulsionBurn-Through Issues with high electrode follow-up high current and welds too close to the edge may cause the expulsion of molten metal during welds.