Welding Oily Metal. Before you start welding ensure the clamp properly connects to the cleaned metal. Dirty rusted oily or otherwise contaminated metal wont hold a weld.

Some welding electrodes build up faster and others will penetrate deeper. A forging operation is applied after the workpieces are heated up. The marks made by this marker are highly visible and illuminate while making your cuts or welding.

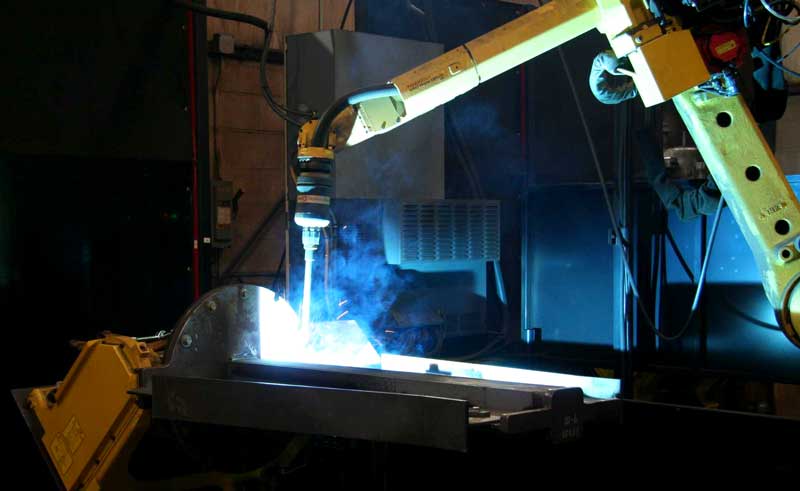

Todays manufacturing shops perform machining and stamping in their facilities typically take parts that have been treated with machining or press oil directly to their welding area.

Cutting too much of the surface off especially if the metal is thin will ruin the strength and shape of the metal. For stainless steel and aluminum that could mean a simple wipe with acetone. Butt welding is a resistance welding process for joining thick metal plates or bars at the ends by directly applying opposing forces with electrodes clamping the workpieces. Cutting too much of the surface off especially if the metal is thin will ruin the strength and shape of the metal.